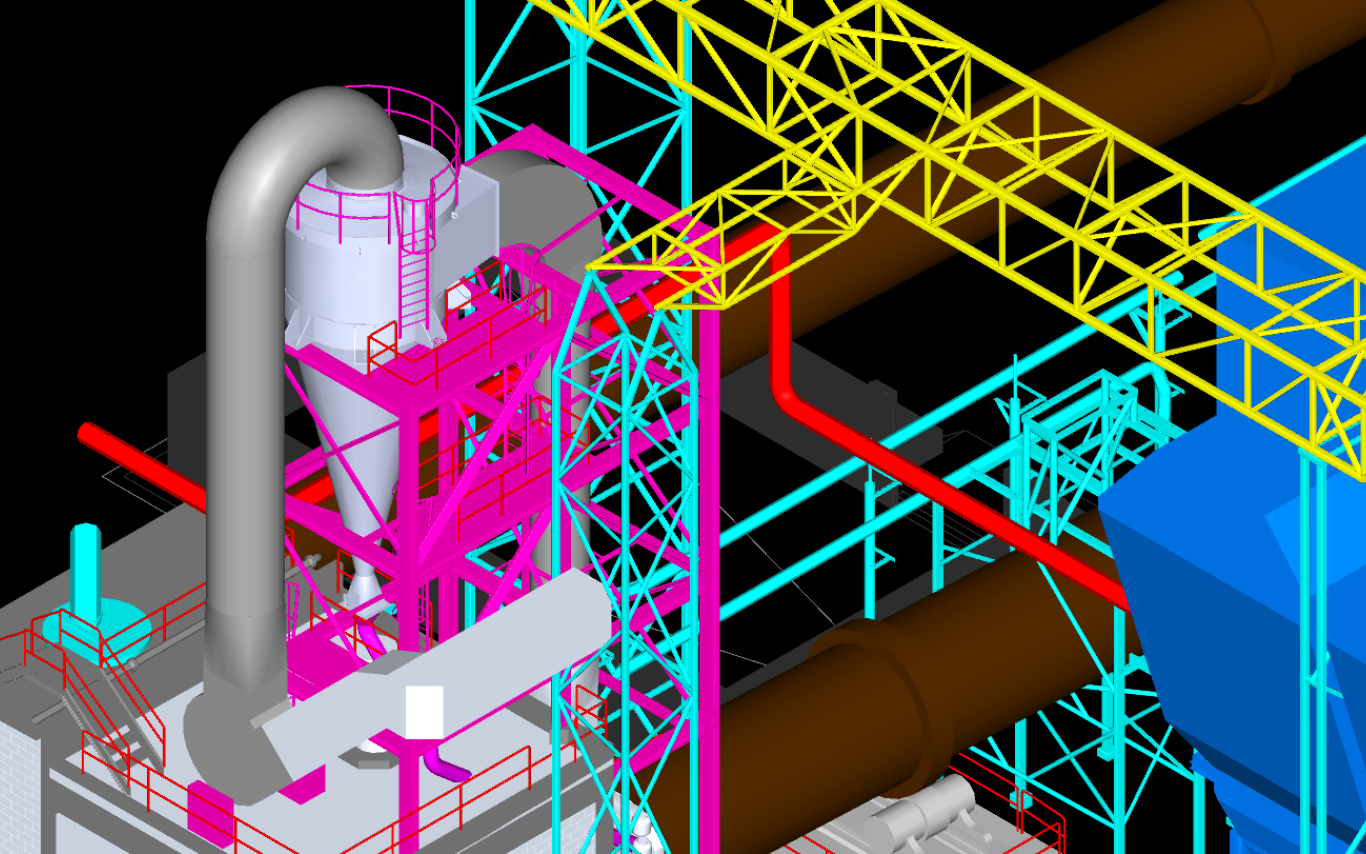

Through the Clean BC Industrial Incentive Program, PE Tech was retained to study the opportunity to reduce fossil fuel consumption and greenhouse gas emissions from their lime kilns by installing a flash dryer on their largest and most efficient kiln. The study examined the potential benefit of installing a lime flash dryer on kiln #3, and to confirm the new equipment would physically fit in the existing crowded facility space. The study identified that by increasing the capacity in the kiln #3, they would be able to shut down kiln #1 and utilize kiln #1 for only occasional peak production. The existing three lime kilns are powered with natural gas and are one of the highest contributors to GHG emissions in the mill. The installation of a flash dryer would both address GHG emissions as well as increase kiln capacity. The objective of this project was to assess which kiln(s) to install the flash dryer at to reduce the overall usage of fossil fuel in the lime kilns, and support efficiencies in production.

As a result of this study, PE Tech identified this upgrade would result in reducing GHG emissions by almost 2,000 tonnes annually. However, the return on investment for this type of incremental savings made this project cost-prohibitive for implementation. PE Tech recommended NFP examine alternative strategies to reduce their GHG emissions with stronger business cases and more effective process savings.

Get in touch with us

Interested in joining our team?

Are you an engineer with a vision? At PE Tech, we're on the lookout for individuals who aren't just looking for a job, but a calling to innovate, create, and make an impact. If you believe your expertise and passion could complement our team, we want to hear from you. Forge your path with us and become a part of something transformative. Please email your resume to info@petech.ca, and let's explore how your skills can redefine our engineering landscape.