Biomass Dryer Flow Optimization

(2019) Terrace, BC

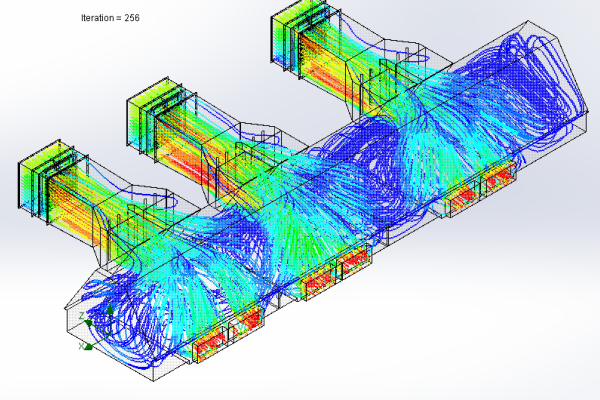

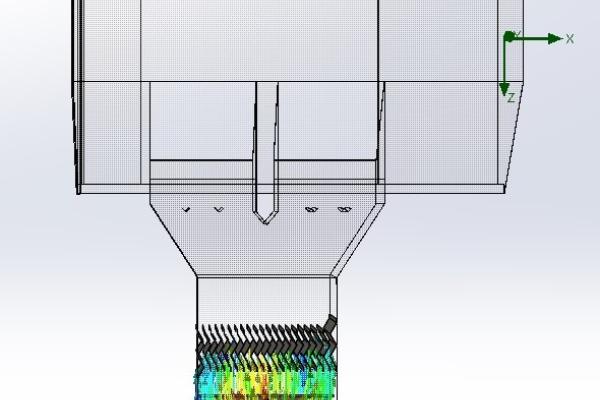

Shortly after commissioning, the client experienced several random fires in their biomass dryer that raised safety concerns and thousands of dollars in damage and lost revenue. After weeks of unsuccessful trials performed by the equipment manufacturer, our team was called in to mitigate the situation. The team implemented an advanced modeling approach which resulted in the creation of a custom spark arrestor that not only eliminated the sparks but it also achieved the goal without increasing the system pressure drop. Further heat modeling of the resultant air stream revealed inadequate mixing, and using the advanced modeling tools the team was able to overcome this secondary issue to create a more homogeneous post burner flow. This added benefit significantly increased the air temperature mixing across the bed, which drastically reduced the hot spots allowing the spark detection system to function properly.

Get in touch with us

Interested in joining our team?

Are you an engineer with a vision? At PE Tech, we're on the lookout for individuals who aren't just looking for a job, but a calling to innovate, create, and make an impact. If you believe your expertise and passion could complement our team, we want to hear from you. Forge your path with us and become a part of something transformative. Please email your resume to info@petech.ca, and let's explore how your skills can redefine our engineering landscape.