Sustainable Energy in Pulp and Paper: Exploring Anaerobic Digesters as a Sludge Treatment Method and Biogas Creation

The future of the pulp and paper industry is increasingly reliant on sustainable and efficient waste management solutions, with the complex challenge of sludge treatment providing extensive scope for improvement. The introduction of anaerobic digestion has served as a promising advancement, although it has not yet been widely adopted in the industry. This process offers the potential to transform pulp and paper effluent waste into a valuable clean energy resource, simultaneously providing a new revenue stream and operational savings.

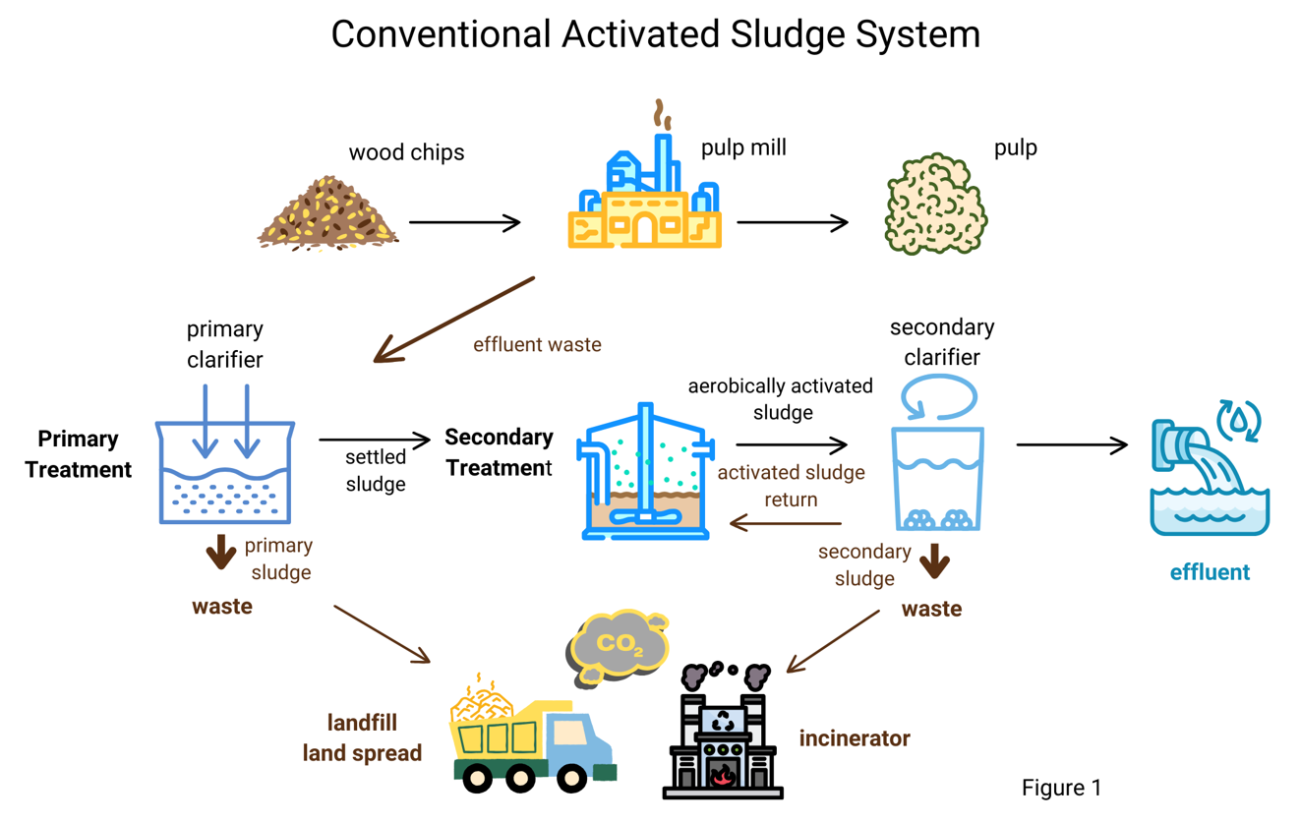

Conventional Activated Sludge (CAS) systems are the current standard for treating effluent in pulp and paper mills. CAS systems begin by separating the sludge through settling, the process of removing lignocellulosic solids in the wastewater, followed by a secondary treatment utilizing aerobically activated microorganisms to remove soluble organic matter (Figure 1). While effective in meeting discharge requirements, the main byproduct of aerobic digestion is carbon dioxide; and the dewatered sludge often represents an increased environmental burden, as disposal requires incineration, landfilling, or land spreading. The water content in treated sludge is such that it must be further dewatered before incineration can occur, rendering the operation reliant on the use of supplemental energy. Landfilling and land spreading allow the sludge to decompose, thereby releasing additional carbon dioxide and methane into the atmosphere, and notably contribute to soil degradation, water contamination, and land occupancy.

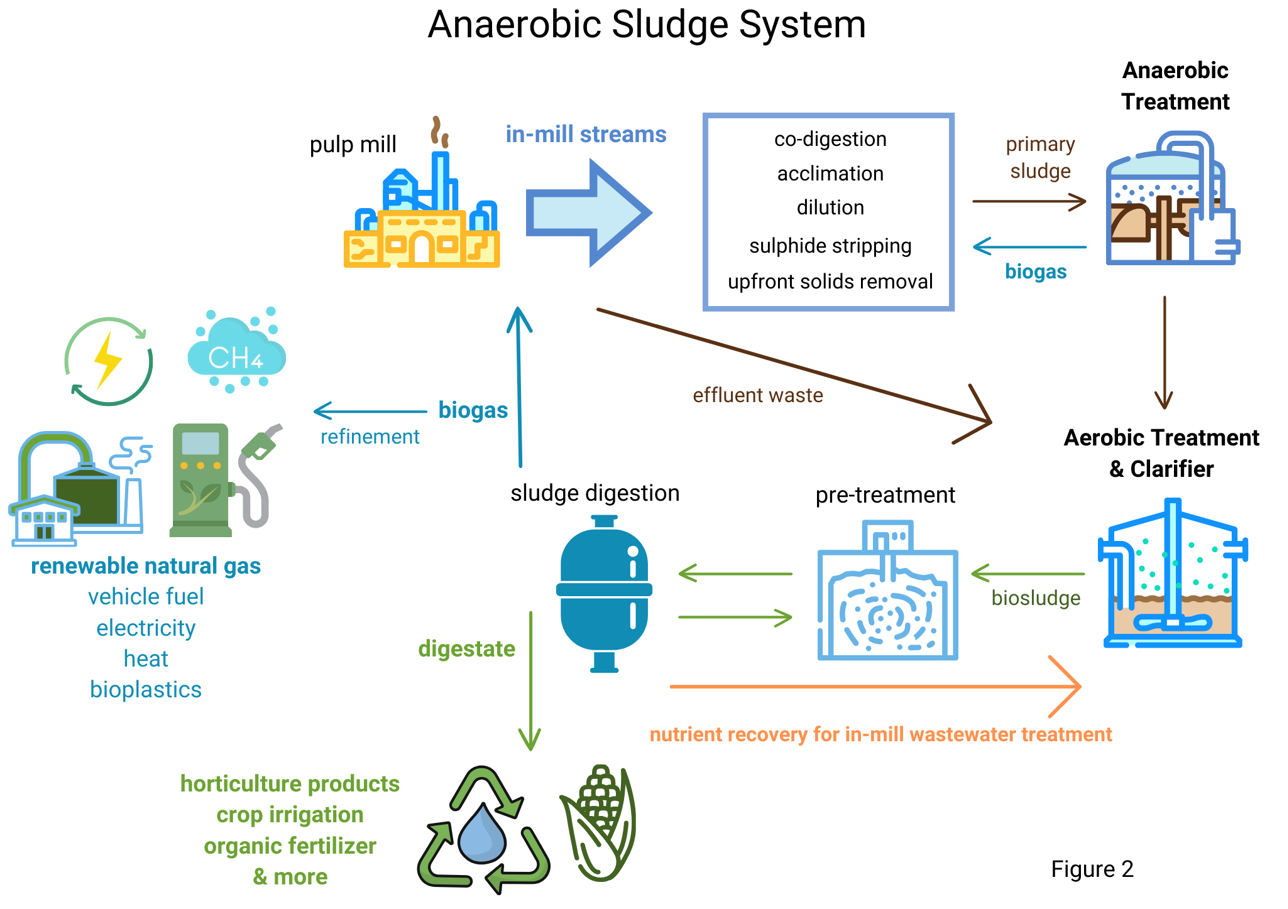

In contrast, anaerobic digestion operates in the absence of oxygen and primarily produces methane and carbon dioxide (Figure 2). This process can significantly reduce Chemical Oxygen Demand (COD) and, to a lesser extent, Biochemical Oxygen Demand (BOD). An aeration tank is still required to eliminate the BOD; however, the overall tank volume and oxygen requirement is considerably less. The resultant biogas, containing about 60% methane, can be used directly as on-site fuel or refined into biomethane, also known as renewable natural gas (RNG). Technologies such as water scrubbing, Pressure Swing Adsorption (PSA), and membrane separation are used to refine the gas to a purity level on par with natural gas, making it suitable for sale to local gas utilities.

Hydrogen sulphide is a trace component of biogas creation that has been shown to inhibit methanogenesis and contribute to equipment erosion and maintenance costs, necessitating a method to manage its removal, along with excess moisture, to enhance viability and fuel value. This is efficiently mitigated through chemical scrubbing, biological desulfurization, or with a packed media bed. Microaeration, the introduction of tiny amounts of oxygen into the digester to regulate the redox potential, has also proven valuable, allowing for stable methane production at a low operational cost. Moisture is routinely removed by compression and cooling, but can also be achieved by passing the gas through an absorbent.

For all its potential, anaerobic digestion in the pulp and paper industry remains a complex task. The effluent from mills, particularly from kraft pulp processes, pose a unique challenge due to the presence of chemical compounds that inhibit microorganism growth and ultimately slow maceration. Fortunately, the addition of pretreatments such as thermal exposure, microwave irradiation, enzyme addition, and pH adjustments have shown tremendous value in improving biogas yield and digestion rate. Moreover, heat required for the elevated temperature applied in thermal pretreatment may be provided from heat recovery systems that take advantage of the surplus available at industrial mill sites, further advancing sustainable technology implementation and benefit.

Broad adoption of anaerobic digestion in the pulp and paper industry has been largely hindered by concern surrounding capital investments, space requirements, and the specific qualities of pulp effluent, despite the potential for kraft mill pulp to produce more methane than other mill types. The environmental benefits it offers, such as reduced greenhouse gas emissions and the production of RNG with resource recovery, make it an enticing option for the future of the industry. Encouragingly, each challenge presented by the method is adequately managed by a number of economically and environmentally sound solutions.

By integrating anaerobic digestion, the industry can move towards a more sustainable approach, reducing its reliance on fossil fuels and contributing to circular economy goals. Although the initial investment requires commitment, the long-term environmental and economic benefits have been effectively demonstrated by the sites that have already incorporated anaerobically treated sludge systems, warranting serious consideration.

The potential for renewable energy production positions anaerobic digestion as a technology to watch in the industry. It remains a strong example of the economic and environmental opportunities sustainable technology provides when strategically employed. Stay tuned to PE Tech for more insights into industry developments and innovative solutions.

About PE Tech

Specializing in the pulp & paper and wood fibre industries, we offer a unique blend of technical expertise and environmental leadership. Our mission is to empower industrial operations with sustainable, efficient, and forward-thinking solutions.